About the Center

At the Tirsan Kardan R&D Center, which was certified by the Republic of Türkiye Ministry of Industry and Technology in 2016, all projects and activities related to cardan shafts and spare parts are managed under one roof in the central building.

Design, simulation, product development and project management activities are carried out in the facility which is built on total area of 3.000 m2. The R&D Center includes a 1.865 m2 test center equipped with the latest technology that will set an example for the sector on a national and global scale.

Tirsan Kardan R&D Center, which stands out with its researcher structure, innovative approach and technical equipment, has science and engineering backgrounds from different disciplines, expert staff in the fields of machinery, materials and metallurgy, mechatronics, physics and chemistry at undergraduate, master’s and doctoral levels. The team of R&D Center works with the aim of meeting the evolving and changing needs of its customers in the process from design to final product.

As a result of the performance evaluation of the Ministry of Industry and Technology, the R&D Center was awarded 1st place in 2018 and 3rd place in 2020 among Group A R&D Centers located in Türkiye.

Tirsan Kardan continues its R&D investments and studies in line with its 2030 vision without slowing down.

Testing and Verification

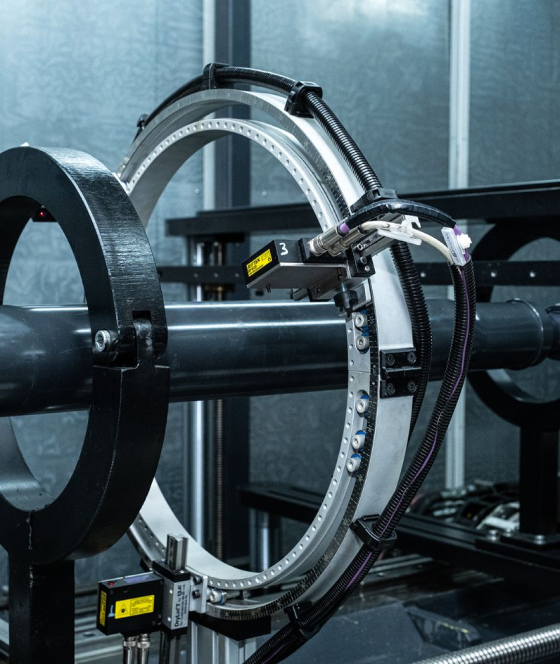

The Test Center located within the Tirsan Kardan R&D Center is among the few examples of the sector on a global scale. The Test Center has a complete infrastructure that can perform all product and process verifications from the assembled product level to independent components.

It verifies the performance of the products through tests and simulations carried out in a virtual environment, followed by accelerated physical tests that simulate real field conditions.

It implements special test plans designed by expert staff, especially in the fields of structural and dynamic durability, acoustic comfort and environmental impact, and whose results are verified with real field conditions.

It can compress vehicle level endurance tests, which take 8-10 months, into a laboratory level test program in a short time period of 8 weeks with the heavy commercial vehicle road simulator with an integrated mud system which the its investment has just been completed.

In addition to testing and verification of new product prototypes, the Test Center also carries out periodic performance tests of our products in mass production.

Research and Development

All conceptual design, virtual simulation and project management stages within the new product design process are carried out at the Tirsan Kardan R&D Center by experienced and expert engineer staff.

Structural and dynamic durability, safety, mechanical vibrations and real field operating conditions of the products in acoustic areas are simulated primarily in a virtual environment using advanced computer-aided design and analysis methodologies. Thus, by eliminating the need for some laboratory and vehicle-level tests, product design cycle times are shortened and product development costs are reduced.

Intellectual Property Rights

Tirsan Kardan R&D Center constantly improves its intellectual property portfolio by producing projects that create added value and contain innovative ideas.

The R&D Center doubled its intellectual property portfolio between 2016 and 2018 and was among the top 50 companies in Türkiye in the registered patent ranking and among the top 10 companies in the registered utility model ranking in 2019. Among the companies operating in the automotive industry, it is among the top 10 companies in the number of patent registrations and in the top 3 companies in the number of utility model registrations. In 2020, it succeeded in being among the top 50 in Türkiye in the registered patent ranking.

110

Total Number of Patent/Utility Model Applications

193

Total Number of Registrations of Patents/Utility Models