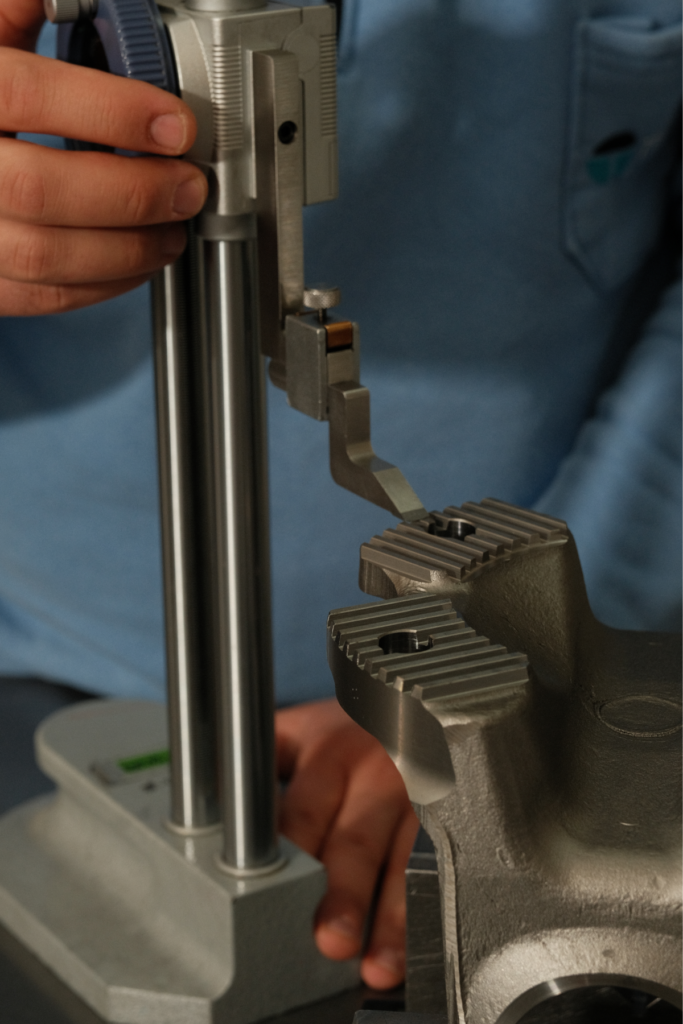

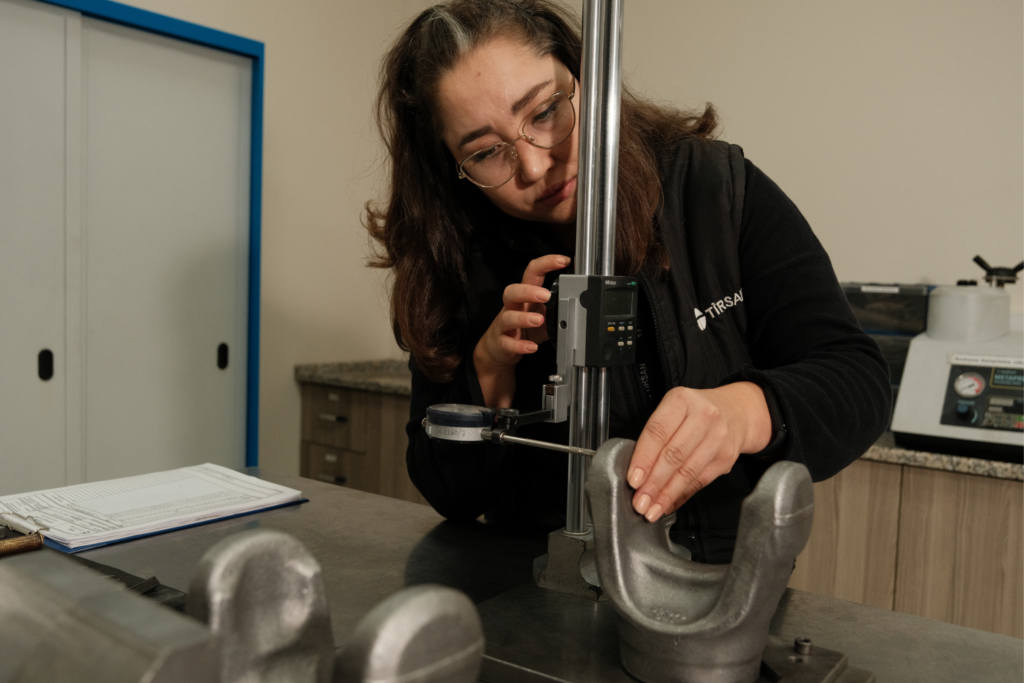

As Tirsan Kardan, we attach importance to our Quality Assurance in accordance with the principle of “Quality is not controlled, It is produced” and the “Customer Satisfaction” we achieve thanks to this. We approach our Quality Control and Assurance Processes with sensitivity, and carry out all metallurgical and measurement controls of Tirsan Cardan shafts, which are produced in accordance with International Quality Standards, from the entry of the raw material to the shipment of the product, completely and meticulously in our own laboratory. We promise our customers the quality, reliability and durability they can rely on, even in the harshest environments.

Examples of the devices and methods we use in our Quality Control Processes are as follows:

- Our CMM Devices (Gear Measurement and Scanning Functions)

- Our Rockwell, Micro Vickers, Brinell Hardness Measurement Methods,

- Our Calibration/Verification Laboratory,

- Our Form Scanning Devices (Linear – Circular)

- Our Profile Projection Devices

- Our Grinding Burn Tests

- Our Metallurgy Laboratory (Sample Cutting – Polishing – Bakelite – Metal Microscope – Stereo Microscope)

- Paint Test Methods Compliant with Standards (Cross Cut – Salt Test)

- Welding Test Methods Compliant with Standards (Bending – Crushing – Opening – Microstructure – Macrostructure – Liquid Penetration – Ultrasound)

- Pipe Test Methods Compliant with Standards (Opening – Crushing – Secretion)

As Tirsan Kardan, we adopt quality practices as a corporate culture, not a requirement, and we constantly improve our quality processes in order to produce zero-defect, trouble-free and reliable products.

Our Certificates

Tirsan Kardan has IATF 16949, ISO 14001, ISO9001 and ISO/IEC 27001 management system certificates to meet the highest quality, environmental and information security standards.